Detergent filling machine

There is a wide variety of detergent products. From foaming to viscous to corrosive products. Finding a detergent filling machine that is versatile enough to handle all of your products and meet your specific requirements can be a real challenge. However, solutions do exist.

Can a single machine fill all types of liquids? Depending on the viscosity of your products, you may work with gravity or with a pump. In any case, a machine with interchangeable nozzles is essential. If you have foaming products, choose a nozzle rather than a plunger nozzle. It is easier to use (as there is no adjustment) and prevents soiling. More information on filling foaming products. For viscous products, valve spouts should be used.

A fast, simple and precise equipment, even for large doses. For this reason, choose a weight filling machine rather than a volumetric or flow filling machine.

Cleanability: choose equipment that can be easily dismantled for cleaning or that can be cleaned in place (CIP). For automatic machines, the presence of a recovery tank will also significantly reduce cleaning time in the event of an incident on the line.

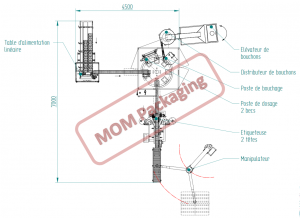

Complete packaging line

To limit the number of operators on a production line, contact a manufacturer directly. He can offer you additional equipment for the start and end of the line, or even a line controlled by a single operator.

For example, you will find :

- Rotary or linear feeding tables, bottle turners, or feeding robots,

- Marking or labelling equipment,

- Quality control elements: vision, checkweigher,…

- Accumulation tables, manipulators, cartoning machines,…

MOM equipment

MOM offers a complete range of detergent filling machines: from high speed filling lines to semi-automatic equipment.

Connected, they allow you to retrieve in real time the individual data of each package. Intelligent, they analyse production data to provide you with decision support.

To simplify format changes, the elements can be dismantled without tools. This is known as plug & play or SMED changeover.

For compact equipment, MOM also builds filling and capping monoblocks.

If you have additional constraints such as: corrosive products, explosive products, ATEX obligation, vapour emissions, we manufacture this type of special equipment.

Find here all the liquid filling machines we manufacture.